- Piping and Boilermaking

- Naval and Industrial Mechanics

- Composite Materials

- Laser Cleaning

- General Repairs and Maintenance

PIPING AND BOILERMAKING

Within the commitment to diversification of our company, the mechanics division is born. Serving the needs of our customers, enhancing the strength and capacity of METAL WELD SUR SERVICE.

- Repair, manufacture and assembly of boilermaking

- Repair, manufacture and assembly of pipes

- Manufacture and assembly of weapons

- Manufacture and assembly of supports and polines

We also have a workshop for the manufacture of boilermaking and machining.

NAVAL AND INDUSTRIAL MECHANICS

Within the commitment to diversification of our company, the mechanics division is born. Serving the needs of our customers, enhancing the strength and capacity of METAL WELD SUR SERVICE. We have created a group of professionals backed by their extensive experience in the development of mechanical activity and their commitment to continuous training. We have naval mechanics, electromechanics, adjusters, turbiners, etc. specialized in:

- Compressor repairs.

- Maintenance.

- Main and auxiliary engines.

- Generators

- Bombs

- Reducers

- Pneumatic and hydraulic.

COMPOSITE MATERIALS

We have the activity of Composite Materials, contributing with it, a wide range in the various repairs carried out on board

- Lifeboat repairs.

- Fiber pipe repairs.

- Repairs in cabins, shower board, non-slip aisles, etc.

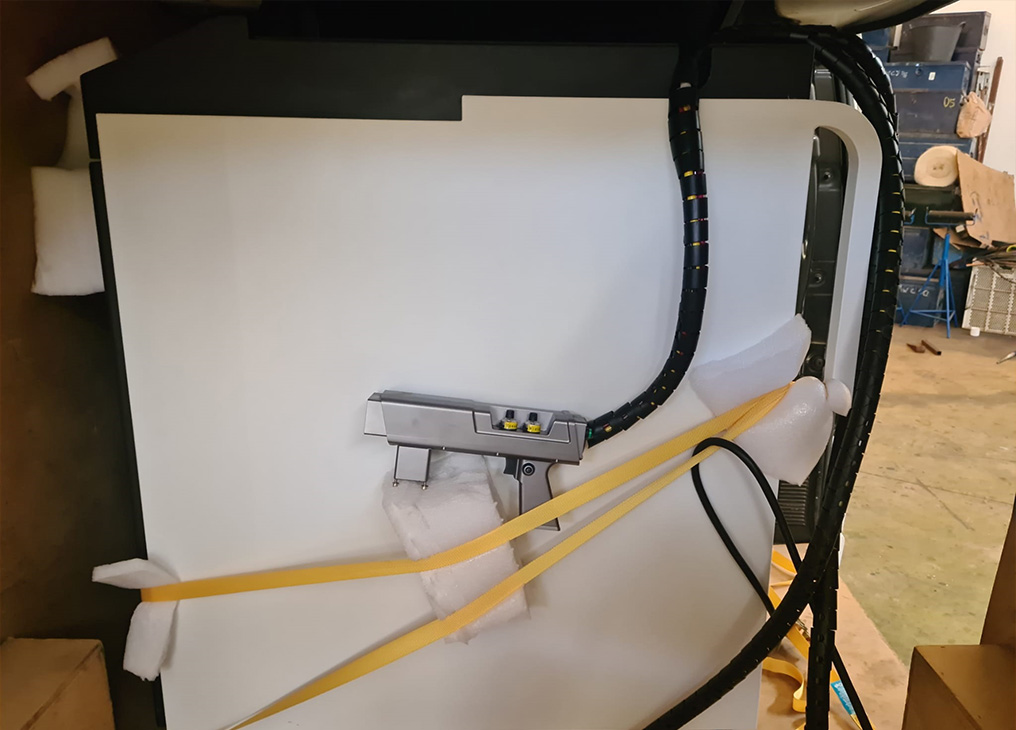

LASER CLEANING

Our fiber laser cleaning systems combine the most sophisticated electronic, optical and mechanical technologies and are characterized by their high degree of integration, due to the built-in cooling units, as well as by the high efficiency of the fiber laser generators used in the LC-GL series.

If we compare with conventional procedures such as blasting, chemicals, dry ice cleaning, or manual, laser cleaning stands out for a number of advantages that we list below:

→ Machining without contact or wear on the tools.

→ Very little influence on the cleaned material.

→ Leaves almost no residue.

→ Don't end up with chemicals in the sewer.

→ Impressive level of quality and reproducibility of the marking.

→ Cleaning in any desired corner.

→ Great flexibility of the process.

→ Possibility of cleaning (up to 100 mm).

→ Fast cleaning speed.

→ Allows a quick and easy start-up in cleaning processes.

System components

- Laser Generator

In fiber laser the light beam amplifier medium is an optical fiber doped with rare earths such as erbium, neodymium, yttrium, diprosium, holmium, praseodymium and thulium. One or more laser diodes are used for pumping, so most fiber lasers are pumped diode lasers.

The advantages of the fiber laser cleaning machine are:

→ Precision: The laser beam of the fiber laser cleaning machine offers an extremely low tolerance, making it much more accurate in addition to being more productive.

→ More Environmentally Sustainable: Other lasers can only convert a small percentage of the power of their power supply into photons, but a fiber laser converts about 70-80% of the energy it consumes.

→ Ease of use: The fiber laser cleaning machine only needs connection to the current and nothing else.

- Galvanometric head

The Laser beam is deflated by digitally controlled deflection mirrors that project it onto a two-dimensional plane. The deflection head can be tilted from 0º to 360º continuously, facilitating adaptation to any inclination/orientation.

- Supply unit

The supply unit and all the components needed to control the Laser source and the galvanometric deflection head are integrated into the source and head. The complete and ready-to-go equipment consists of two modules including:

→ DC-power supply, for the generation of DC voltages

→ Fiber Laser resonator, for the delivery of laser light through an optical fiber

→ Optical coupler, to collide the energy to the dial head with the necessary optical elements

→ Laser interface, to control and monitor all components

→ Laser control, for the control of laser beam emission

Applications and Industry

REMOVAL OF RUST AND CORROSION: They can be used to remove and remove rust from small machines or materials kept for some time in the open.

CLEANING OF PAINTS: Allows to remove paint of all kinds in steel structures.

RESTORATION: In the restoration process, laser cleaning has been used with satisfactory results in, for example, the conservation of stones to remove fouling.

WELD CLEANING: Preparing the material for welding processing in the steel sector is vital. Laser cleaning systems can be integrated into production lines.

GENERAL REPAIRS AND MAINTENANCE

Specialized in the various Repairs and Services on board. For this we have specialized personnel, for different repairs to be carried out:

- Pipe downspouts jams.

- Imbornal.

- Hotel Services Machinery.

- Crystal polishing

- Repair of vinyl floor and parket.

- Spare parts

- Etc.